Assemblage automatisé & Solutions optiques

Manufacturing & Assembly

ABF is the Authorized system builder for Flex Link since 1987 with hundreds of solutions and installation including pallet assembly, Robot cells infeed conveyors, automated and manual work cells for the electronic industry and more. Flex Link has a full line of pallet handling system ranging from single track series conveyors (X65P, X85P, XKP) to twin track (XT) series ready for automation based on configurable standard modules.This makes it very easy and fast to create simple as well as advanced layouts for routing, balancing, buffering and positioning of pallets.

Our product mix combined with our engineering and manufacturing capabilities allowed us over the years to tackle a huge and diversified number of customer needs in the automation of manufacturing.

Our installed systems are handling refrigerators, kitchen ranges, washing machines, lamps and lighting fixtures, computer chips and substrates, coffee makers, children toys, automotive parts, water heaters, explosives, safety air bags, snow mobiles and watercrafts sub assemblies, electrical terminal boxes and many more.

Optical Solutions

In the optical industry, there are several keys factors to success and with FlexLink, solutions, here is how we can help give you a competitive edge

Quality and precision for maximum output and yield

Le concept Smart Routing ™ de Flex Link ’s Smart Routing™ concept, automatically routes trays containing the lens blanks to the blocking, polishing and beveling machines for processing that precisely follows the optical prescription instructions. This high level of automation, with 100% process control greatly reduces throughput time and breakage, which lowers your overall costs.

Specialized technology

Flex Link has special teams working with new technologies specifically for improving lab performance and lowering costs. For example, Flex Link Visualize™ system has been developed to allow labs to go paperless, along with VisionX®, which is a modular space saving solution, specifically developed for the optical industry.

Ability to quickly respond to new production demands

Our compact and modular solutions enable you to quickly redesign your line to meet new production demands. Through our global network, we can assist you wherever you’re located in making step-by-step investments and providing the service level that your lab requires.

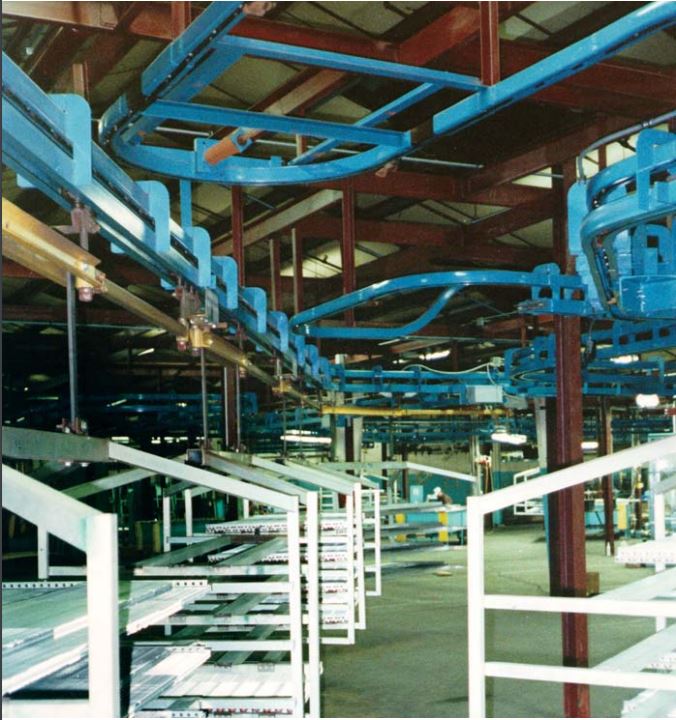

Metallurgy

ABF Systems is a commercial partner representing Jervis B. WEBB and we supply the Aluminum plants with small to medium integrated product handling projects.

Webb represents the most original and advanced technology in the market and ABF Systems is proud to be part of this by supplying and integrating the WEBB line locally.

ABF Systems offers you also a full line of Automatic Guided Cart (AGC). SmartCart, a Webbproduct, is an Automatic Guided Vehicle (AGV) solution yet more cost-effective and easier to integrate, install and operate. Guidance is ensured by magnetic tape allowing you to quickly install or modify the guide path making it more flexible compared to the AGV family of product. Whether you are in the business of running an Electrowinning System or an Aluminum Smelter, you can count on ABF Systems and our business partner Jervis B. Webb to provide a full range of process and delivery conveyors. We offer a complete range of inverted and overhead conveyor lines to meet your requirements that include; initial studies, inspection reports, basic and detailed engineering, service and replacement parts, modification and or complete installations and commissioning.

Our experience in the aluminum industry has been extensive in the Rodding Shops, this demanding environment utilizes a Power and Free (P&F) conveyor for transferring anodes and spent rods to various process including stub heating, casting stations, spray stations, butt removal and rod straightening operations.

In the nickel, cobalt, copper and zinc industries we offer complete conveyor systems that are either supported from the building trusses or floor supported structures utilized primarily but not limited to electroplating process. These systems often involve robotic loading and unloading requiring a high degree of product position accuracy and repeatability. We can offer these systems with enamel or epoxy top coat finishes and or complete with stainless conveyor sections for high moisture environments.

Our professional staff respond quickly to all inquires to keep your production moving forward.

Automotive

Our product handling solutions for the Automotive industry span from small part feeding with low profile chain and belt conveyors to heavy duty overhead rivetless chain conveyors. We also develop and integrate special devices for the assembly line.

We are teamed up with the leaders in the market such as Jervis B. WEBB, FlexLink, Dorner and OMNI Metalcraft to provide the most efficient and the best product to suit your need.

ABF Systems offers you also a full line of Automatic Guided Cart (AGC). SmartCart®, a Webbproduct, is an Automatic Guided Vehicle (AGV) solution yet more cost-effective and easier to integrate, install and operate. Guidance is ensured by magnetic tape allowing you to quickly install or modify the guide path making it more flexible compared to the AGV family of product.

ABF Systems is the commercial partner of the top suppliers of standard equipment for the automotive industry.

Jervis B. Webb is the leader in automotive systems and ABF is proud to be part of the success of such a market leader. With the Webb product and ABF engineering and know-how, we can design the most advanced and durable conveyor system for the automotive manufacturers in Canada. Our Jervis B. Webb product long and proven history makes it the most reliable on the market today. Combined with our in-house solutions and ingenuity, the Webb line of material handling products is the best solution of a global product on a local level serving your exact needs for automation.

The Webb products include:

- The Unibilt® Enclosed Track Overhead conveyor,

- the Power and Free,

- the Towveyor® towline conveyors,

- • as well as other related products such as the Automatic Guided Carts (AGC), also known as SmartCart®.

Flex Link is the top plastic chain conveyor system in the world and offers a complete line of pallet based handling solutions ranging from Single Track to Twin Track solutions primarily to tier two and three manufacturers within the automotive industry. The wide range of standard solutions and the system’s modularity enables future expansions and modifications in a cost effective way. The Flexibility of Flex Link conveying system makes it a first choice and safe investment. The Flex Link products include: XK and its single track pallet system and XT twin track with its wide range of pallets to suite your requirements.