Cosmétiques & Pharmaceutiques

Cosmetic & Personal care

Providing turnkey automated solutions to multinational companies has given ABF Systems Inc. the experience required to be the preferred supplier of choice when handling your products.

Conveying, counting, and case packing of blister packs, conveying and ergonomic roll stations of I.V. sets, conveying, high speed transferring, accumulation and case packing of sanitary pads and diapers are just a few examples of applications ABF Systems Inc. has provided for our customers.

Our solutions in the cosmetic and personal care industry are diversified:

- Sanitary wash down conveyors for liquid and viscous filling lines.

- Puck handling systems for those hard to convey products whether to fill or to transport finished products.

- Vacuum belt conveyors to stabilize light unstable containers before filling.

- Compact conveyors for overhead machine bypass in tight packaging departments.

- Small foot print Alpine Accumulation system.

- Vertical transportation to clear floor space.

- Full packaging line of conveyors with tight radius curves to maximize floor layouts.

- Special machines and devices designed to fit the usual needs of the industry.

ABF systems designed and installed partial and complete lines for the following domains:

Shampoo, liquid soap, mouth wash, creams, antiperspirant, perfume, baby powder, lipstick, feminine sanitary pads and tampons, baby diapers, Adult incontinence diapers, and other products.

Medical & Lenses

ABF Systems has provided solutions for medical devices, manufacturing andpackaging for major companies in this field. Some examples are catheter tubes, pills boxes and bottles transportation and pallet-based accumulation, electrolyses and lenses. We provide conveyors and assembly modules, manufacturing and packaging as well as work stations and indexing devices.

Medical supplies and devices:

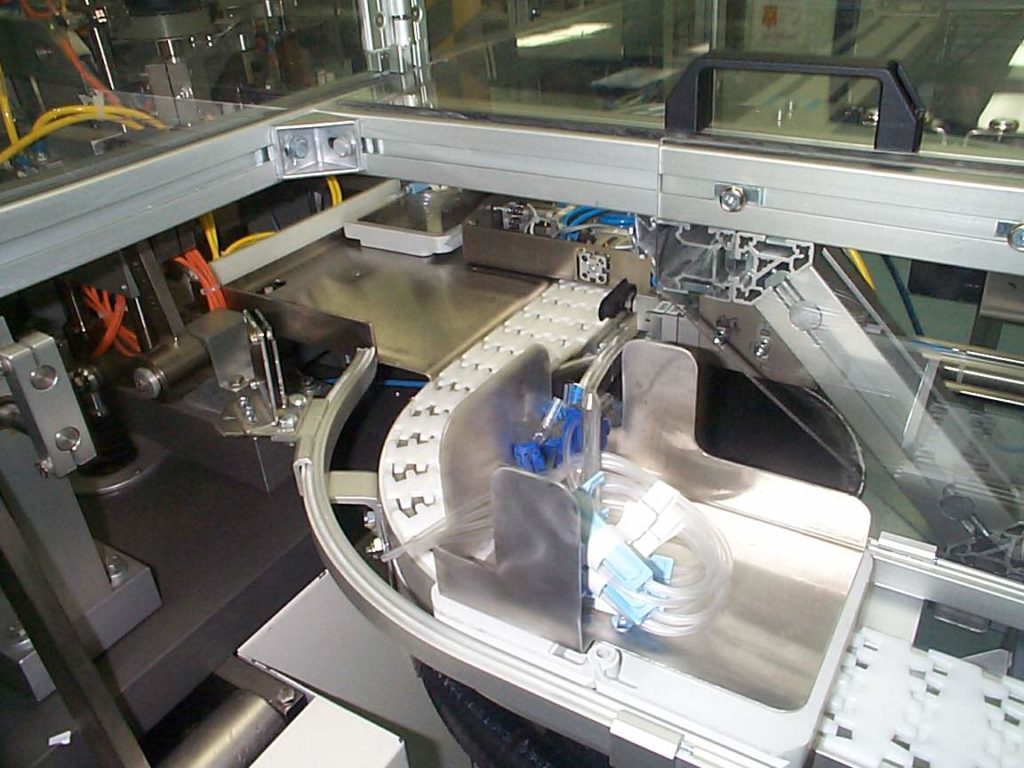

ABF Systems supplies conveyor systems for the transportations of unpacked and packed catheter devices. Whether it is to link manual work stations and collect the prefinished catheter assemblies or to feed and collect subassemblies from automatic machines, we can help you design the right conveyor line as well as special pick and place devices to achieve the best production logistics in this field.

We designed a unique and simple accumulation and transportation system for loose catheter subassemblies coming out of an automatic assembly machine, keeping them well stacked and untangled so they are easy to pick-up on the manual work stations for final assembly.

We also supplied conveyors and transfer pushers to handle trays of syringes and to them in ‘’hot chambers’’ in the medical radioactive process. Our standard series of low-profile compact foot print conveyors helped our customer in designing the best suited system for the application in the smallest area possible.

Optical lenses

We supplied a very large number of conveying systems designed for the lens production and finishing industry. Our experience and lab process knowledge will help you achieve the optimal layout with the right proven tray conveying system to better connect your process machines any guessing. Everything is already thought of and we have standard solutions to respond to all you tray handling needs with minimum space and easy access to machines.